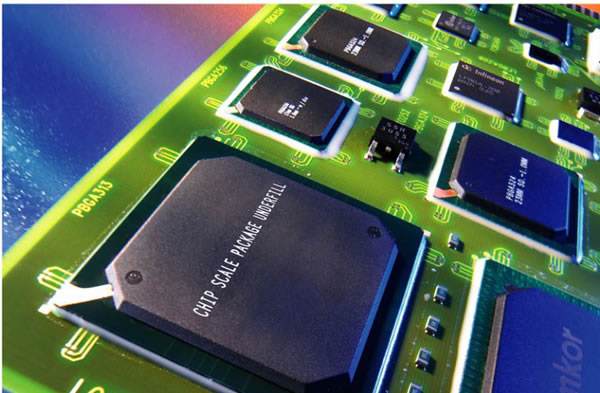

H907-U是一种单组分环氧密封粘接剂,用于CSP或BGA底部填充制程及各类电子元组件、温度敏感产品、摄像头模组等之粘接固定、密封保护等。它能形成一致和无缺陷的固化胶层,能有效降低由于硅芯片与基板之间的总体温度膨胀特性不匹配或外力造成的冲击,具有较低之膨胀性。受热时能快速固化。较低的粘度特性使得其能更好的进行底部填充、元件粘接及产品密封保护等。

特性:

固化前 外观 黑色、淡黄色

粘度(mPa.S) 1500-3500 @25℃

密度 1.2g/cm3

固化后 玻璃转移化温度 80℃

硬度 75-85shore D

剪切强度 15Mpa

表面电阻 1.5×10*15ohm/cm(25℃)

体积电阻 2.5×10*16ohm/cm(25℃)

耐电压 16-18kv/mm(25℃)

硬化条件

1、在 150℃ 固化时间约为5-10分钟

2、在 130℃ 固化时间约为10-20分钟

注意:粘结部位可能需加热一定的时间以便能达到固化的温度。固化条件会因不同的装置而不同。

H907-u is a one-component epoxy sealing adhesive, which is used for the bottom filling process of CSP or BGA and the bonding, fixation and sealing protection of various electronic components, temperature sensitive products, camera modules, etc. It can form a uniform and defect free curing adhesive layer, which can effectively reduce the impact caused by the overall temperature expansion characteristics mismatch or external force between the silicon chip and the substrate, and has low expansion. It can cure quickly when heated. The lower viscosity makes it better for bottom filling, component bonding and product sealing protection.

characteristic:

Appearance black and light yellow before curing

Viscosity (MPa. S) 1500-3500 @ 25 ℃

Density 1.2g/cm3

Glass transfer temperature after curing 80 ℃

Hardness 75-85shore D

Shear strength 15MPa

Surface resistance 1.5 × 10 * 15ohm / cm (25 ℃)

Volume resistance 2.5 × 10 * 16ohm / cm (25 ℃)

Withstand voltage 16-18kv / mm (25 ℃)

Hardening conditions

1. Curing time at 150 ℃ is about 5-10 minutes

2. The curing time at 130 ℃ is about 10-20 minutes

Note: the bonding part may need to be heated for a certain time to reach the curing temperature. Curing conditions will vary depending on the device.